Harmonic Drive is a strain wave gear which can improve certain characteristics compared to traditional gearing systems.Harmonic Drive is trademarked by the Harmonic Drive company. The strain wave gear was invented in 1957 by C.W. Musser.

They are typically used in industrial motion control, machine tool, printing machine, robotics and aerospace, for gear reduction but may also be used to increase rotational speed, or for differential gearing.

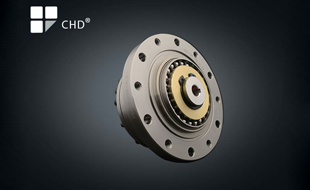

Composition of harmonic gear drive device

Harmonic gear drive device mainly consists of three basic parts, i.e. wave generator, flexspline and rigid spline.

Wave generator:It is composed of flexible bearing and oval cam. Wave generator is generally equipped at the input end of reducer with internal circle of flexible bearing fixed on the cam and elastic deformation of external circle to oval shape realized by means of roll balls.

Flexspline:It is a part of thin-walled elastomer carrying external tooth circle,which is generally equipped at output end of reducer.

Rigid spline:It is a part of rigid round ring carrying internal tooth circle, in general, it holds 2 more gear teeth than those of flexspline. The rigid spline is usually fixed on the body of reducer machine.

Harmonic gear drive principle

When harmonic wave is used as reducer, wave generator is active, rigid spline is fixed, and flexspline takes output form.

When wave generator is loaded into internal circle of flexspline, flexspline is deformed to oval shape due to elasticity, then flexspline teeth at long axis place are inserted into rigid spline trough, thus complete meshing status is realized. At this time, two wheels of gear teeth at short axis place do not contact completely, in other words, at the disconnected position. In the process from meshing to disconnection, the harmonic gear drive is at the status of meshing out or meshing in.

When wave generator rotates continuously, flexspline is deformed unceasingly, two wheels of gear teeth will change their own working status from meshing in, meshing, meshing out to disconnection, thus the so-called wrong tooth movement happens, finally movement transmission from active wave generator to flexspline is achieved.

Characteristics of harmonic gear drive

High precision:Multiple teeth simultaneously mesh at two symmetry positions of 180°, hence, error of gear teeth space and accumulated error of teeth space impact evenly on rotation precision, therefore, extremely high position and rotation precision can be obtained.

Big transmission ratio:Single transmission ratio of harmonic gear can reach i=30~500, furthermore, the structure is very simple, and three fundamental parts on the

same axis can easily achieve high reduction ratio.

High bearing capacity:During harmonic gear drive, teeth meshing belongs to surface contact, furthermore, comparatively more teeth can mesh together simultaneously, therefore, unit area bears small load, and load capacity is higher than that of other transmission forms.

Small size and light weight:Compared with ordinary gear device, harmonic gear can significantly reduce size and weight, thus, miniaturization and light weight can be achieved in production.

High transmission efficiency and long life.

Smooth transmission, free shock and little noise.

Business activities

S

more

China Harmonic Drive (CHD®) have harmonic drive reducer & harmonic drive components set & CHD Actuators.

With G Gear Technique, lower noise, higher design freedom, high stability, high precision, big torque, high life, high speed ratio, small size, our products are widely used in robot, aerospace, digital controlled lathe, semiconductor processing machine and precise mechanical drive control, especially meet the special requirements in robot industry.

Robotics and automation, aerospace, Defence and homeland security, Medical equipment, Semiconductor technology, machine tools, filling and closing machine, Printing and Paper converting Machines and packaging Machines.

The reducer assembly must be carried out within a very clean environment. It is not allowed any foreign objects to go inside the reducer during the assembly, otherwise it may damage the reducer in the course of usage.

Our staff of sales and technical support is available to help you in selecting the right protection for your application as well as to provide you with samples of our products for evaluation. 24 hours hotline is valid to support all the time.